The Complete Guide to BAG LED Driver Suppliers: Quality, Performance, and Selection

Introduction:BAG LED Drivers

In the rapidly evolving world of LED lighting technology, the role of a reliable LED driver cannot be overstated. As businesses and consumers increasingly shift toward energy-efficient lighting solutions, understanding the importance of quality LED drivers—particularly BAG LED drivers—has become essential. At Sarlux Electronics, we’ve dedicated ourselves to providing top-tier LED driver solutions that meet the demanding requirements of modern lighting applications.

This comprehensive guide explores everything you need to know about BAG LED drivers, from their fundamental operation to selecting the right supplier for your specific needs.

Understanding BAG LED Drivers: The Foundation of Quality Lighting

What Are BAG LED Drivers?

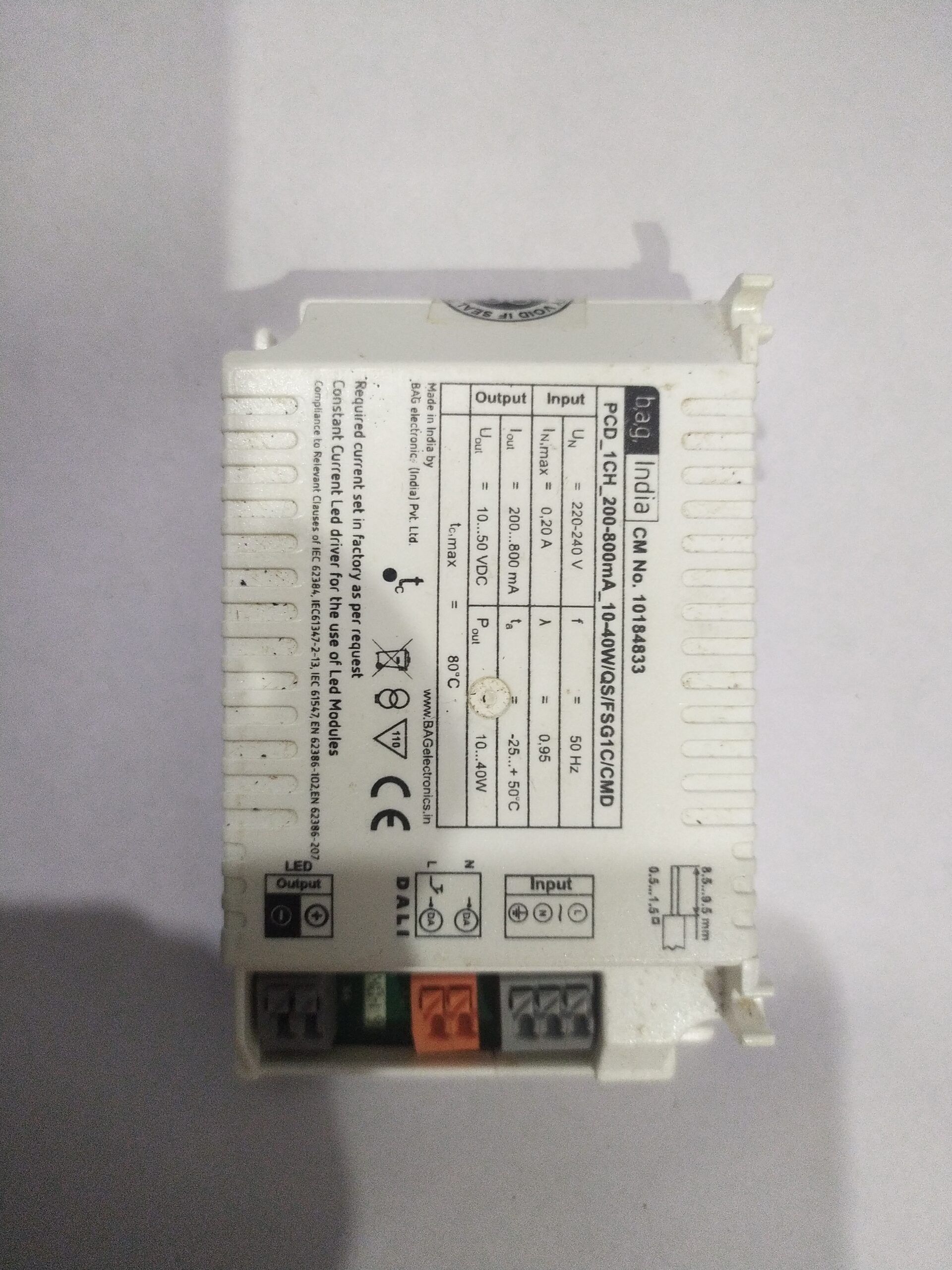

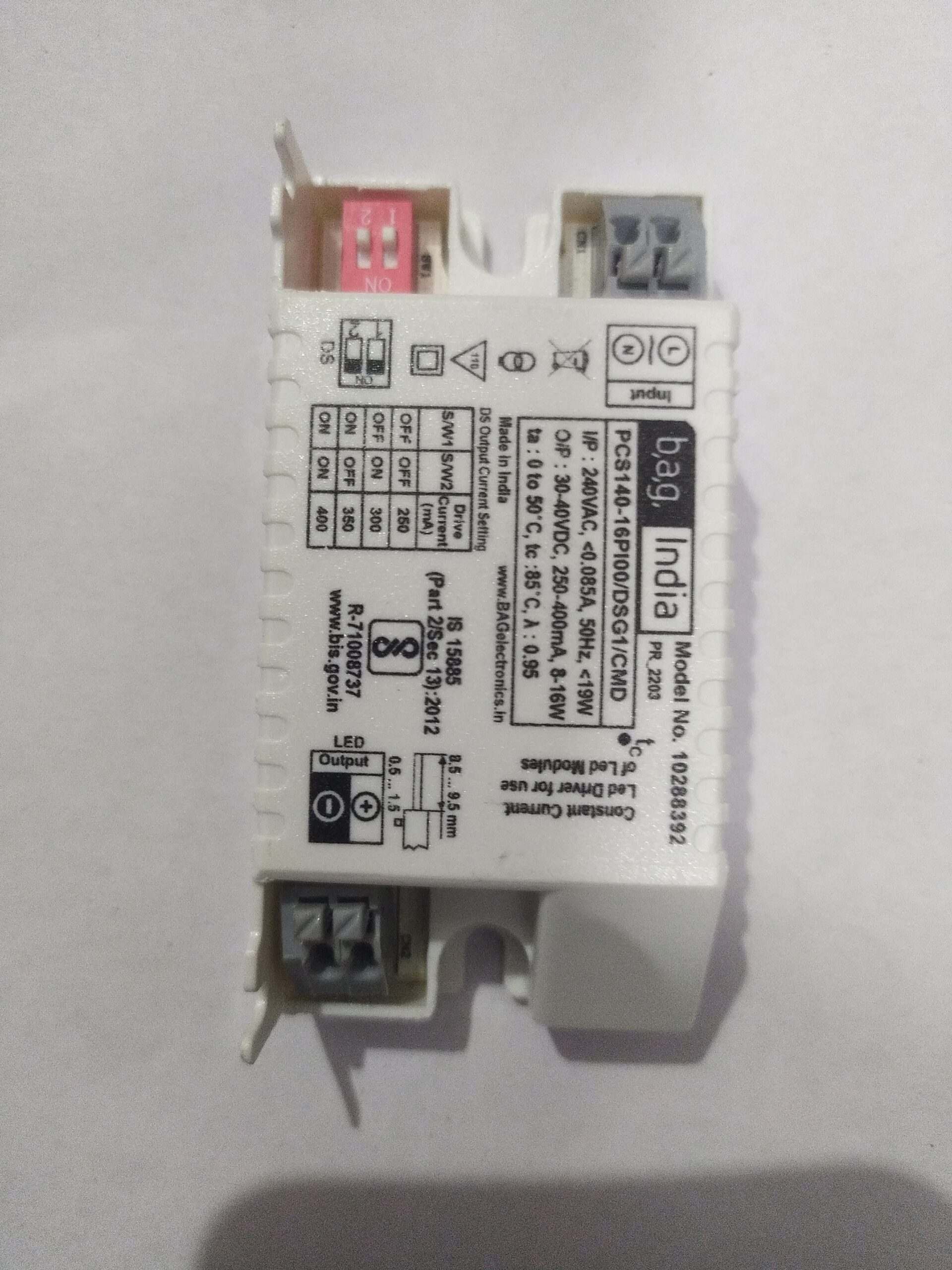

BAG LED drivers represent a category of high-performance power supply units specifically engineered to regulate and control the electrical current flowing to LED lighting systems. Unlike traditional lighting technologies that operate directly on line voltage, LEDs require precisely controlled direct current (DC) to function optimally and maintain their longevity.

The term “BAG” in LED driver terminology often refers to drivers that meet specific quality standards and performance benchmarks established for commercial and industrial applications. These drivers are designed with advanced circuitry that ensures stable output, protection against electrical anomalies, and compatibility with various LED configurations.

How LED Drivers Work

LED drivers perform several critical functions:

Current Regulation: LEDs are current-driven devices, meaning their brightness and lifespan depend on receiving a consistent current level. LED drivers convert alternating current (AC) from the power grid into regulated DC while maintaining the precise current output needed by the LED array.

Voltage Conversion: Most LED systems require lower voltage than what’s supplied by standard electrical outlets. LED drivers step down voltage from 120V, 240V, or 277V AC to the appropriate DC voltage level required by the LED configuration.

Protection Mechanisms: Quality BAG LED drivers incorporate multiple protection features including over-current protection, over-voltage protection, short-circuit protection, and thermal management systems that prevent damage to both the driver and LED components.

Types of LED Drivers

Understanding the different types of LED drivers helps in making informed purchasing decisions:

Constant Current Drivers: These maintain a fixed current output while allowing voltage to vary within a specified range. They’re ideal for LED arrays where consistent brightness across all LEDs is critical.

Constant Voltage Drivers: These supply a fixed voltage output, commonly 12V or 24V DC, and are typically used in LED strip lighting and applications where the LED array has its own current regulation.

Dimming Drivers: Advanced BAG LED drivers often include dimming capabilities compatible with various control protocols including 0-10V, PWM (Pulse Width Modulation), DALI (Digital Addressable Lighting Interface), and TRIAC dimming systems.

The Importance of Quality LED Drivers in Lighting Applications

Performance and Efficiency

The quality of an LED driver directly impacts the overall performance of your lighting system. Premium BAG LED drivers from reputable suppliers like Sarlux Electronics offer efficiency ratings often exceeding 90%, meaning minimal energy is wasted as heat during the conversion process. This efficiency translates to:

- Lower operating costs over the system’s lifetime

- Reduced heat generation requiring less cooling infrastructure

- Smaller carbon footprint for environmentally conscious projects

- Compliance with energy codes and green building standards

Longevity and Reliability

A well-engineered LED driver can last 50,000 hours or more under proper operating conditions. However, inferior drivers may fail prematurely, causing:

- Unexpected maintenance costs and system downtime

- Flickering or inconsistent light output that affects user experience

- Potential damage to connected LED components

- Safety hazards in critical applications

Investing in quality BAG LED drivers from established suppliers ensures your lighting infrastructure operates reliably for years, protecting your initial investment and minimizing total cost of ownership.

Application-Specific Requirements

Different lighting applications demand specific driver characteristics:

Commercial Buildings: Require drivers with dimming capabilities, long service life, and compatibility with building management systems.

Industrial Facilities: Need robust drivers that can withstand harsh environmental conditions including temperature extremes, humidity, and vibration.

Outdoor Lighting: Demand drivers with weatherproof enclosures rated for wet locations, wide operating temperature ranges, and surge protection.

Specialty Applications: Such as horticultural lighting, aquarium lighting, or medical facilities may require drivers with specific output characteristics and certifications.

Key Features to Look for in BAG LED Drivers

Power Factor Correction (PFC)

Power factor measures how effectively electrical power is converted into useful work output. LED drivers with active PFC maintain a power factor above 0.9, which:

- Reduces strain on electrical infrastructure

- Lowers electricity costs in facilities with power factor penalties

- Ensures compliance with regulations in many jurisdictions

- Improves overall system efficiency

Total Harmonic Distortion (THD)

THD measures the quality of the current waveform drawn from the power grid. Quality BAG LED drivers maintain THD levels below 20%, preventing:

- Interference with other electronic equipment

- Overheating of electrical distribution components

- Reduced efficiency in the electrical system

- Potential violations of electrical codes

Surge Protection and Safety Certifications

Professional-grade LED drivers incorporate surge protection to safeguard against voltage spikes caused by lightning strikes or grid fluctuations. Look for drivers with:

- Surge protection ratings of 4kV or higher

- UL, ETL, or CE certification for safety compliance

- IP (Ingress Protection) ratings appropriate for the installation environment

- Compliance with relevant electrical and building codes

Thermal Management

Effective thermal management extends driver lifespan significantly. Quality designs feature:

- Aluminum housing for efficient heat dissipation

- Strategic component placement to minimize hot spots

- Temperature derating curves that show performance across operating ranges

- Thermal protection circuits that prevent damage from overheating

Selecting the Right BAG LED Driver Supplier

Technical Expertise and Support

A superior LED driver supplier doesn’t just sell products—they provide comprehensive technical support throughout the project lifecycle. At Sarlux Electronics, we offer:

Pre-Sales Consultation: Our engineering team helps you select the optimal driver configuration for your specific application, considering factors like LED specifications, dimming requirements, environmental conditions, and budget constraints.

Custom Solutions: When off-the-shelf products don’t meet your needs, we can develop customized driver solutions tailored to unique requirements.

Installation Guidance: We provide detailed installation instructions, wiring diagrams, and troubleshooting support to ensure successful implementation.

Post-Sales Support: Our commitment continues after purchase with warranty service, technical assistance, and product education.

Product Range and Availability

Comprehensive inventory is crucial for meeting diverse project needs. A quality supplier should offer:

- Multiple wattage options from low-power (10W) to high-power (500W+) drivers

- Various output configurations and voltage ranges

- Different form factors including enclosed, open-frame, and chassis-mount designs

- Dimming and non-dimming variants

- Indoor and outdoor rated options

Quality Assurance and Testing

Reputable BAG LED driver suppliers implement rigorous quality control processes:

Component Selection: Using premium components from trusted manufacturers ensures consistent performance and reliability.

Burn-In Testing: Extended operational testing under stress conditions identifies potential failures before products ship.

Environmental Testing: Subjecting drivers to temperature cycling, humidity exposure, and vibration testing verifies performance across specification ranges.

Safety Certification: Independent testing by recognized laboratories confirms compliance with safety standards.

Competitive Pricing and Value

While cost is always a consideration, the cheapest option rarely provides the best value. Evaluate:

- Total cost of ownership including energy consumption and maintenance

- Warranty terms and replacement policies

- Bulk purchase discounts for large projects

- Technical support value and availability

Applications of BAG LED Drivers

Commercial Lighting

From office buildings to retail spaces, commercial environments demand reliable, efficient lighting that creates productive and welcoming spaces. BAG LED drivers enable:

Task Lighting: Providing consistent, flicker-free illumination for workstations, meeting rooms, and specialized work areas.

Accent Lighting: Highlighting merchandise, architectural features, or artwork with precisely controlled light levels.

General Illumination: Efficient ambient lighting for corridors, lobbies, and common areas with optional dimming for energy savings.

Industrial Applications

Manufacturing facilities, warehouses, and processing plants require robust lighting solutions that withstand challenging conditions:

High Bay Lighting: Powerful LED systems illuminating large open spaces from significant heights require drivers capable of handling high-wattage LED arrays.

Hazardous Locations: Specialized drivers with appropriate certifications for explosive atmospheres or corrosive environments.

Machine Vision Systems: Ultra-stable drivers providing consistent illumination for quality control and automated inspection systems.

Architectural and Decorative Lighting

Creating visual impact through lighting requires precise control and flexibility:

Facade Lighting: Weather-resistant drivers powering LED systems that transform building exteriors into dynamic canvases.

Cove and Indirect Lighting: Dimming-capable drivers enabling smooth transitions and scene control for ambiance creation.

Color-Changing Systems: Advanced drivers compatible with RGB, RGBW, and tunable white LED technologies.

Outdoor and Street Lighting

Municipal and commercial outdoor lighting demands durability and efficiency:

Streetlights and Area Lighting: Drivers with photocell compatibility, surge protection, and wide operating temperature ranges.

Parking Structures: Reliable illumination for safety and security with minimal maintenance requirements.

Landscape Lighting: Low-voltage drivers for accent lighting, pathway illumination, and outdoor architectural features.

The Sarlux Electronics Advantage

Our Commitment to Quality

At Sarlux Electronics, we understand that LED drivers are the critical link between power infrastructure and LED lighting performance. Our commitment to quality manifests in:

Rigorous Supplier Vetting: We partner exclusively with manufacturers who demonstrate consistent quality, ethical business practices, and commitment to innovation.

Comprehensive Testing: Every driver model in our portfolio undergoes extensive evaluation to verify specifications and performance claims.

Continuous Improvement: We actively seek customer feedback and monitor industry developments to enhance our product offerings and services.

Industry Experience and Knowledge

With years of experience in the LED lighting industry, our team brings valuable expertise to every project:

- Understanding of electrical codes and compliance requirements across different jurisdictions

- Knowledge of emerging technologies and industry trends

- Practical installation experience informing product recommendations

- Relationships with complementary suppliers for complete system solutions

Customer-Centric Approach

We recognize that every project is unique, and we tailor our approach accordingly:

Flexible Ordering: From single units for testing to bulk orders for major projects, we accommodate various purchase quantities.

Fast Turnaround: Extensive inventory and efficient logistics ensure quick delivery to keep projects on schedule.

Educational Resources: We provide technical documentation, installation guides, and training materials to empower customers.

Responsive Communication: Our team is readily available to answer questions, address concerns, and provide updates.

Future Trends in LED Driver Technology

Smart and Connected Drivers

The integration of LED drivers with IoT (Internet of Things) platforms is transforming lighting control:

Wireless Connectivity: Drivers with built-in Bluetooth, Wi-Fi, or Zigbee capabilities enable smartphone control and remote monitoring.

Data Collection: Advanced drivers can report energy consumption, operating hours, and performance metrics for facility management optimization.

Predictive Maintenance: Analyzing driver operating parameters helps predict failures before they occur, enabling proactive maintenance.

Enhanced Efficiency Standards

Ongoing improvements in driver technology continue to push efficiency boundaries:

- Next-generation topologies achieving 95%+ efficiency

- Reduced standby power consumption meeting strict energy standards

- Advanced thermal management extending component lifespan

- Miniaturization enabling integration into smaller fixtures

Expanded Dimming Capabilities

Sophisticated dimming and control options are becoming standard:

Deep Dimming: The ability to dim to 1% or lower without flicker or dropout Smooth Transitions: Refined algorithms preventing visible steps during dimming operations Multi-Protocol Support: Single drivers compatible with various control systems Color Tuning: Integration with tunable white and color-changing LED technologies

Installation Best Practices

Proper Sizing and Configuration

Correct driver selection prevents performance issues:

Match Driver Output to LED Requirements: Verify that driver current and voltage specifications align with LED array requirements, accounting for series/parallel configurations.

Consider Headroom: Select drivers rated for at least 20% more capacity than the calculated LED load to ensure reliable operation and longevity.

Account for Environmental Factors: Choose drivers rated for the installation environment’s temperature range, humidity levels, and exposure conditions.

Electrical Installation Considerations

Proper installation ensures safety and performance:

Wiring Practices: Use appropriate wire gauge for the current load and distance, following NEC (National Electrical Code) or local electrical code requirements.

Grounding: Ensure proper grounding of all components to prevent shock hazards and electrical noise issues.

Dimmer Compatibility: Verify compatibility between drivers and dimming controls, and follow manufacturer wiring diagrams precisely.

Accessibility: Install drivers in locations that permit ventilation and allow for future maintenance or replacement.

Testing and Commissioning

Thorough testing prevents problems after installation:

- Verify correct voltage and current output before connecting LED loads

- Test dimming functionality across the full range if applicable

- Check for proper thermal performance under operating conditions

- Document installation details for future reference

Maintenance and Troubleshooting

Preventive Maintenance

Regular maintenance extends system life:

Inspection Schedule: Periodically inspect drivers for signs of overheating, corrosion, or physical damage.

Cleaning: Keep ventilation openings clear of dust and debris to maintain proper cooling.

Connection Checks: Verify that all electrical connections remain secure and free from corrosion.

Performance Monitoring: Track energy consumption and light output to detect gradual degradation.

Common Issues and Solutions

Understanding typical problems accelerates resolution:

Flickering: Often caused by incompatible dimmers, loose connections, or driver failure. Check dimmer compatibility and wiring integrity first.

Premature Failure: Usually results from inadequate ventilation, over-driving LEDs, or poor-quality components. Ensure proper installation conditions and driver sizing.

Dimming Problems: May stem from incorrect minimum load, incompatible control systems, or wiring errors. Verify system compatibility and proper installation.

Reduced Output: Can indicate driver degradation, LED aging, or thermal derating. Check operating temperatures and consider driver replacement.

Conclusion

Selecting the right BAG LED driver supplier is a critical decision that impacts the performance, reliability, and cost-effectiveness of your lighting investment. Quality drivers from reputable suppliers like Sarlux Electronics ensure that your LED lighting systems operate at peak efficiency, deliver consistent performance, and provide years of reliable service.

By understanding LED driver technology, recognizing quality indicators, and partnering with knowledgeable suppliers, you can confidently specify and install lighting systems that meet your specific requirements while providing excellent value.

At Sarlux Electronics, we’re committed to being more than just a supplier—we’re your partner in achieving lighting excellence. Whether you’re retrofitting existing facilities, designing new construction projects, or developing innovative lighting products, our team stands ready to provide the expertise, products, and support you need for success.

Ready to Get Started?

Contact Sarlux Electronics today to discuss your LED driver requirements. Our experienced team will help you select the optimal BAG LED driver solutions for your specific applications, ensuring superior performance, reliability, and value. Let us demonstrate why leading professionals trust Sarlux Electronics for their LED driver needs.